LKQ Europe's goal is to be leaders in electrification, from identifying new technology, through to market launch. In addition to advancing workshops through training from our LKQ Academy, we offer many wear parts and various workshop equipment for hybrid and electric vehicles. We also regularly add new components.

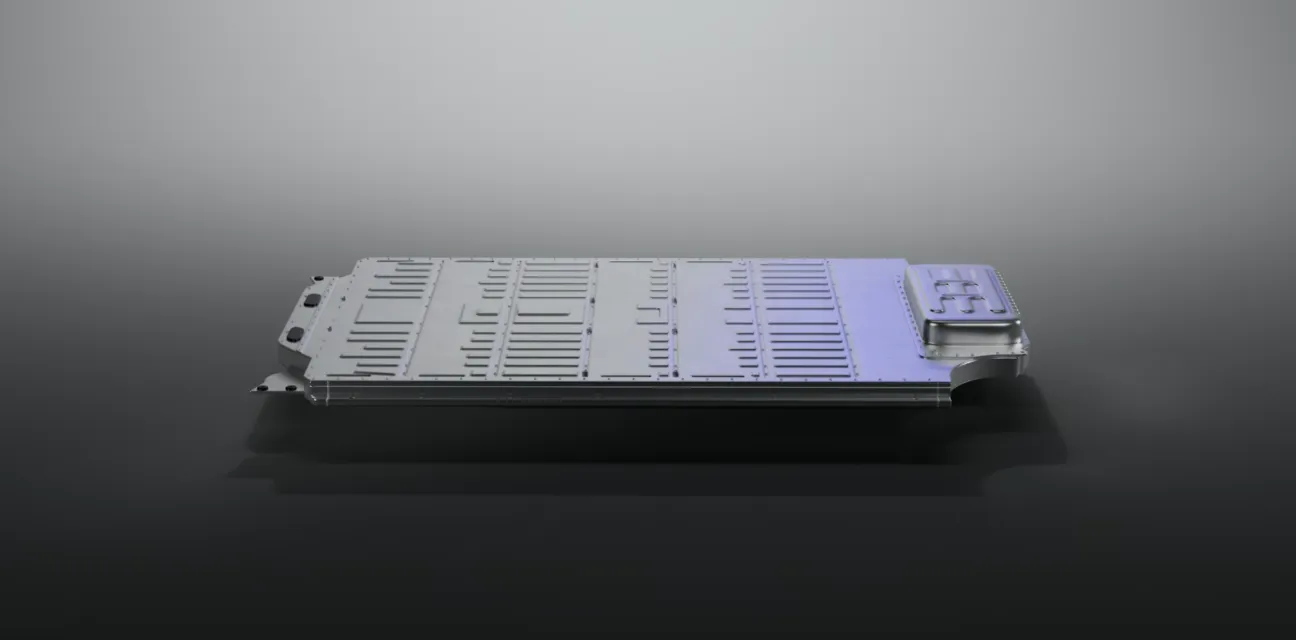

The traction battery is the most valuable part of a battery electric vehicle and lasts between 10-14 years before it needs to be replaced. This raises the key question of what happens to a battery when it’s defective? Raw material scarcity, emission reduction targets and cost considerations all call for sustainable, long-term solutions. LKQ Europe has teamed up with RWTH Aachen University in Germany, to develop solutions for battery reuse, remanufacturing, repair and recycling that foster a sustainable future.

Electrification is one of the most important technology trends worldwide and a rapidly developing global market. It includes hybrid technology, battery-electric mobility or fuel cells.

The technological leap brings new challenges for workshops. LKQ Europe estimates that battery-electric vehicles will require up to 40% fewer parts needed in the future. More than 90% of vehicles sold in 2030, will also be equipped with driver assistance systems, reducing the number of required accident repairs.

New developments require employees to be trained in high-voltage systems, new diagnostic software and equipment, which requires greater investment. Our innovative services, such as the LKQ Academy, and our Europe-wide training program, enables our customers to prepare for this profound change.